Repair and replace the protection lens of the laser cutting head to ensure the service life of the laser cutting head

At Raysoar, we extend a warm reminder to our clients on the importance of laser cutting head maintenance. The use of inferior protective lenses not only jeopardizes the lifespan of cutting heads but also leads to various operational challenges, impacting factory processing, quality, and increasing overall production costs. In this

Upgrade for Laser Cutting Equipment in Yancheng, Jiangsu

In the competitive landscape of China’s laser cutting market, the stability and efficiency of equipment directly impact a company’s production efficiency and costs. However, when equipment issues arise, the high cost of repairs and prolonged downtime often impose significant pressure on businesses. Such was the predicament faced by XX customer in Yancheng, Jiangsu. This customer utilized a MAX 6KW laser cutting machine equipped with a 6KW IPG fiber laser. Recently, the equipment encountered issues with cutting through thick plates and required a significant reduction in speed for normal air cutting. Upon inspection of the laser’s working logs, engineers identified four modules experiencing sudden anomalies, causing the laser power to drop to a mere 2960W. Despite restoring the power to 4060W through file reconfiguration, three modules remained burnt. Faced with exorbitant repair costs and the unstable state of the remaining modules, Raysoar proposed a more cost-effective solution—replacing the entire laser with a new MAX laser source. This suggestion captured the customer’s attention. After a detailed comparison, the customer discovered that the new laser offered a 2-year warranty, and

Expert Solution for Auxiliary Gases for Laser Cutting & Welding

In the era of Industry 4.0, laser cutting technology has become increasingly vital in the manufacturing sector, owing to its precision and efficiency. To meet the market demand for high-quality and efficient cutting, Shanghai-based Raysoar Technology has conducted in-depth research and proudly presents a groundbreaking solution – the FineCutting Laser

Raysoar FWA1500 handheld laser welding machine: the perfect combination of welding efficiency and quality

In today’s rapidly developing industrial age, efficient and high-quality welding equipment is crucial for the competitiveness of enterprises. To meet this demand, Raysoar has launched the all-new FWA1500 handheld laser welding machine. This advanced welding device will provide an unprecedented welding experience, helping you significantly increase productivity while ensuring welding

Raysoar’s Welding Mate: High-Purity Nitrogen for Innovative Laser Welding

In today’s high-tech manufacturing industry, laser welding has become an important processing method. However, this process requires high-purity nitrogen as a protective gas. Welding Mate, a protective gas solution specifically designed for laser welding, is changing the landscape of the laser welding industry with its high-purity nitrogen gas and superior

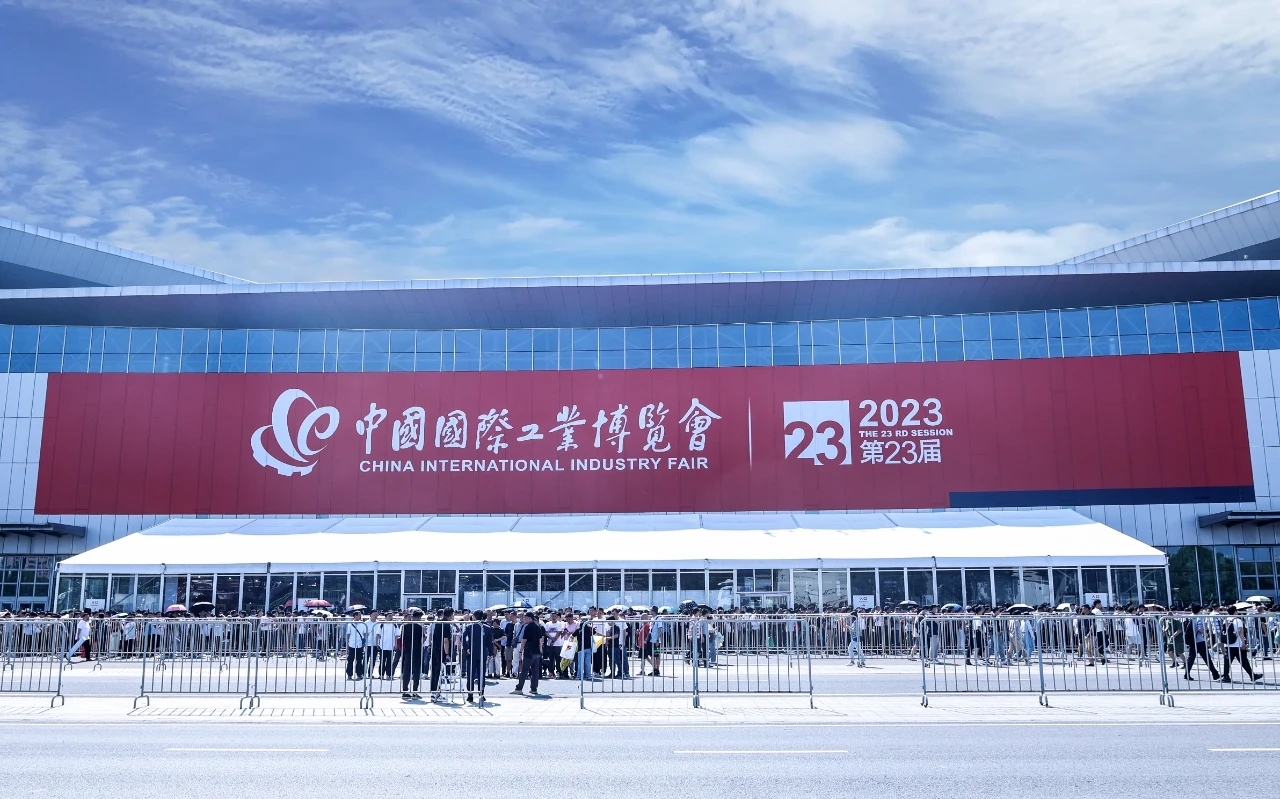

New Welding Tools from Raysoar at the 23rd China International Industry Fair

Welcome to the 23rd China International Industry Fair held in the National Convention and Exhibition Centre in Shanghai! Raysoar brings new welding tools: Fine Welding -series to global customers in the field of laser welding application. This is a handheld welding product configured with the disruptive air-cooling fibre laser source made by

How to Choose the Lower Protective Lens of the Laser Cutting Head

In laser cutting equipment parts, the lower protective lens is one of the consumables with a very high replacement frequency. The lower protective lens is a “double-sided fence” in the external optical path of the laser, which not only needs to resist the harsh environment of external processing, prevent the

The 23rd CHINA INTERNATIONAL INDUSTRY FAIR 2023

The 23rd China International Industrial Fair will be held from September 19th to 23rd, 2023 at the National Convention and Exhibition Center (Shanghai), with 9 major professional exhibitions and a planned area of 280000 square meters. It is expected that more than 2600 exhibitors will participate. The 22nd China Industrial

Guide to Proper Nozzle Selection for Laser Cutting

Laser cutting is universally recognized in the manufacturing industry for its high efficiency, high quality and high precision metal cutting. Even so, there are still many factors affecting laser cutting, of which the correct choice of laser cutting nozzle is particularly critical. Cutting different types of metal materials, cutting different

Precitec Laser Cutting Head Repair, Laser Sensor Failure Repair

Raysoar can repair all models of Precitec cutting heads, including Procutter 1.0, Procutter 2.0, Lighcutter 1.0, Lighcutter 2.0, and more. The following is a list of common Precitec cutting head failures. 1. Optical component failure repair The Precitec cutting head is an important part of the laser cutting system and its optics (e.g., lenses) are critical to the quality of the cut. When the optics are damaged or worn out, the cut quality will be affected. The collimator focusing lens is damaged and burned out, Raysoar offers a repair service to replace the collimator focusing lens or lens set replacement. Replacement of upper and lower protective lens and seals. 2. Focusing motor failure Damaged steel belt replacement, damaged collimator lens set replacement. 3. Circuit board failure Cutting head circuit repair. 4. Indicator light alarm The cutting head alarms when there is a malfunction. When the indicator light is on it reflects different damage information, all led lights are off, a red light is on, a red light blinks 3 times per second, a red light blinks once per second, and so on. It can indicate many different types of malfunctions including power supply conditions, damaged optics, air pressure issues, upper and lower protective mirror issues, and more. By using the temperatures of the cutting head, collimator set, focusing lens set, and lower protective mirror shown on the ProCutter APP temperature mirror, identify the area of the high-temperature warning and use your hand to touch the corresponding area on the outside of the cutting head while the cutting head is stopped, to determine if the temperature value shown by the APP is true. If the hand temperature is normal, but the APP temperature display is obviously too high or unstable, and the second LED or the fourth LED lights up red, please send the cutting head to Raysoar Technology for inspection and repair. Cutting Head Sensor Fault Repair. Sensor Repair Service Items: 1. Sensor Thimble Repair 2. Nozzle Connector Pin/Pin Seat Repair 3. BNC Sensor Pin Seat Repair 4. Sensor Circuit Repair 5. Sensor Circuit Replacement 6. Broken Sensor Body Repair 7. Amada Sensor Body Break Repair 8. Amada Sensor Insulated Seat Replacement 9. Sensor Threaded Nut Repair 10. Sensor Lower Head Repair 11. Sensor Airtightness Repair Sensor repair process: 1.customer fault description; 2.Send your sensor to us; 3.Check the sensor and provide a quote. 4.Confirm the quotation and payment. 5.Repair the sensor and provide the repair service report. 6.Send the sensor back to the customer. 7.Online technical support for after-sales service. 8.Repair the sensor free of charge, and we will bear the cost for the same fault after repair, except for the fault caused by improper operation or collision. Share: Facebook Twitter Pinterest LinkedIn Contact us