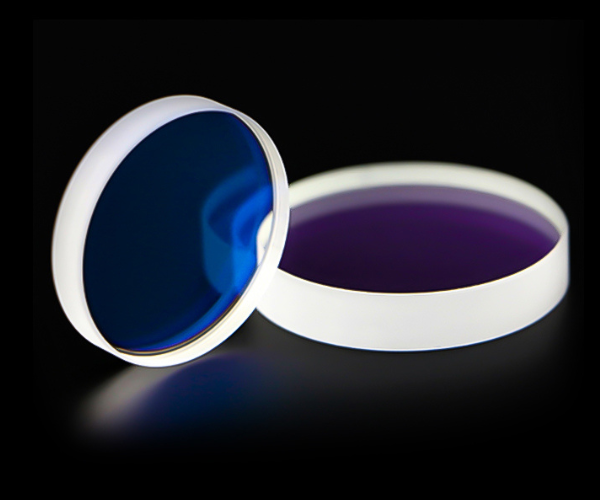

Laser Protection Window

High Temperature And Slag Resistance

Precision Machining

Durability

High transmittance

Temperature and slag resistance

Fused Silica

Safe and easy

Features of laser protection window

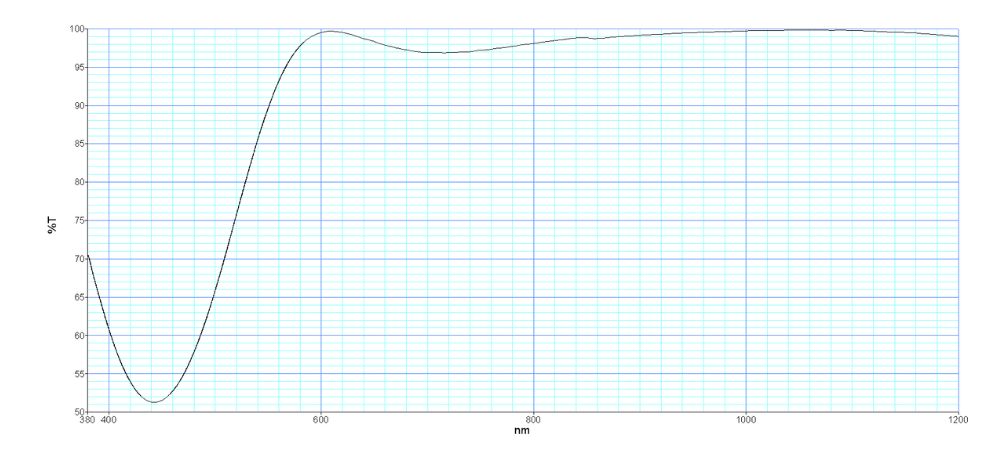

Adopt double-sided high damage threshold anti-reflection coating, the light transmittance is above 99.5%, which greatly reduces the loss caused by laser reflection

Imported Substrate

The imported high purity fused silica ensure excellent optical, thermal and mechanical performances.

Precision Machining

Made from good quality substrate and by the processes of slicing, polishing and burnishing.High temperature and laser resistance.

Double Coating

By AR-AR coated with the transmittance over 99.5%, the protective window greatly reduces the power loss caused by laser reflection.

Protective angle

The full edge is machined in 0.5mm 45 'angle so as to ensure the safe operation without hurting hands.

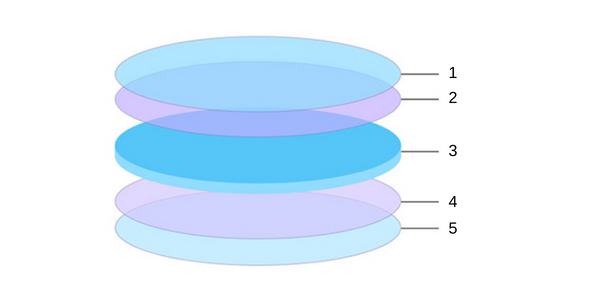

Double-sided coating

Adopt double-sided high damage threshold anti-reflection coating, the light transmittance is above 99.5%, which greatly reduces the loss caused by laser reflection

1.Scratch and wear resistant coating

2.Anti-reflection coating for both sides

3.High purity fused silica

4.Anti-reflection coating for both sides

5.Scratch and wear resistant coating

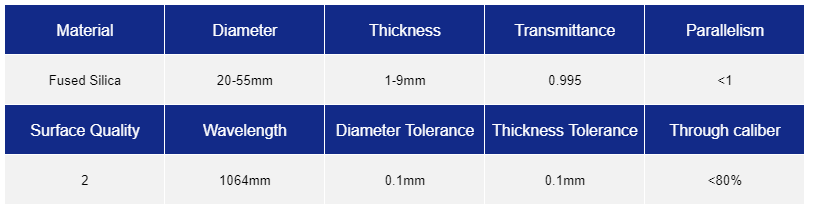

Product Specifications

Installation & Maintenance

Replacement of the protective window

1.Loosen the two lock nuts on the protective window assembly and pull out the protective window cartridge.

2.Note: PIs seal the open area of the laser head immediately with a non-adhesive protective film after the window is removed !

3.Pls make sure to put the protective window cartridge (includling the window) in a clean environment for maintenance.

4.Tear off the protective film on the laser head, insert the well maintained protective window carriage (including the window) flat into the laser head and lock it.

5.Note: PIs make sure the protective window carriage is inserted in the correct direction!

6.Pls fasten the two lock nuts on the protective window assembly with hands in appropriate force.