Guide to Proper Nozzle Selection for Laser Cutting

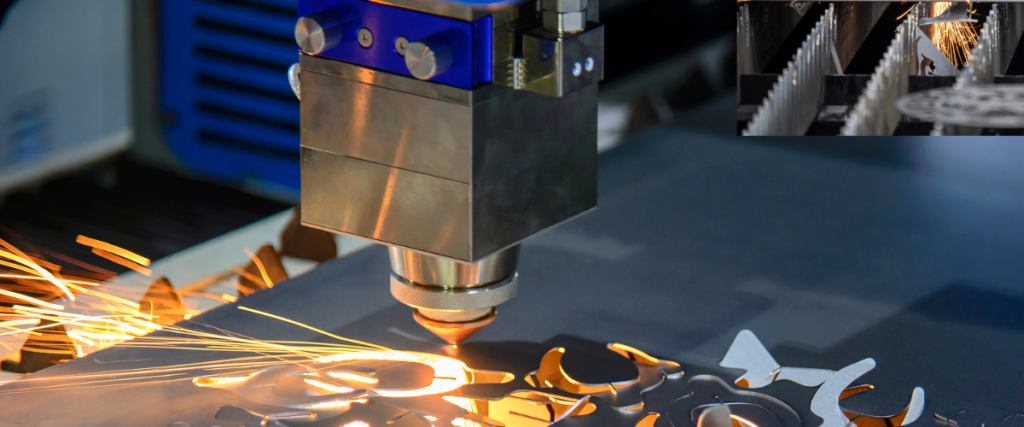

Laser cutting is universally recognized in the manufacturing industry for its high efficiency, high quality and high precision metal cutting. Even so, there are still many factors affecting laser cutting, of which the correct choice of laser cutting nozzle is particularly critical. Cutting different types of metal materials, cutting different thicknesses of the same type …

Guide to Proper Nozzle Selection for Laser Cutting Read More »